Determination of indentation hardness can be done for substances classified as vulcanized (thermoset) rubber, thermoplastic elastomers, cellular materials, elastomeric materials, gel-like materials, and some plastics. Durometer scale is a type of measurement of rubber material’s hardness. Generally most rubber materials fall under the Scale Shore A whereas Hard rubber and plastics use Shore D. Hardness of other materials such as Foams and soft sponges are judged using scales Shore O, OO and by scale Asker C.

Behaviour of rubber material when a tensile force is applied is determined. Test is performed to evaluate the tensile properties rubber materials, such as Tensile strength, Elongation at break and Modulus. Different test specimens can be used for the test as per various international standards. Tensile related properties are also evaluated for the products under conditions. MAEON laboratories is equipped with state of the art instrument to determine the required stress-strain properties.

Testing for the property of tear resistance of thermoplastic elastomers and conventional vulcanized thermoset rubber are performed in MAEON laboratories using different shapes of specimens as per the standard chosen

The compression set taking place under constant stress / strain in media / air is evaluated. The test is intended to measure the ability of rubber to retain elastic properties after prolonged compressive stress

The test determine the compression-deflection characteristics of rubber material other than those usually classified as sponge rubber and hard rubber.

This test determine the compression-deflection characteristics of rubber material other than those usually classified as sponge rubber and hard rubber.

Polymer, Plastics and Rubber, undergo changes both Physical and chemical – MAEON laboratories can conduct tests to quantify the property changes during the ageing tests under Heat, Oxygen, fuel, oils, chemicals etc.

Rubber products are used under exposure to Chemicals, Oils, Greases, Fuels and othe fluids. The Rubber material undergo deterioration on contact with these substances. The effect of such contact on physical properties can be evaluated.

The test method is used to determine the adhesion strength between plies of fabric bonded with rubber or the adhesion of the rubber layer in items made from rubber, and attached to other material.

Determination of Adhesive strength of rubber to rigid materials, such as Metal, Plastics. Different Standard test samples are prepared for Adhesion test, based on each application as per product application.

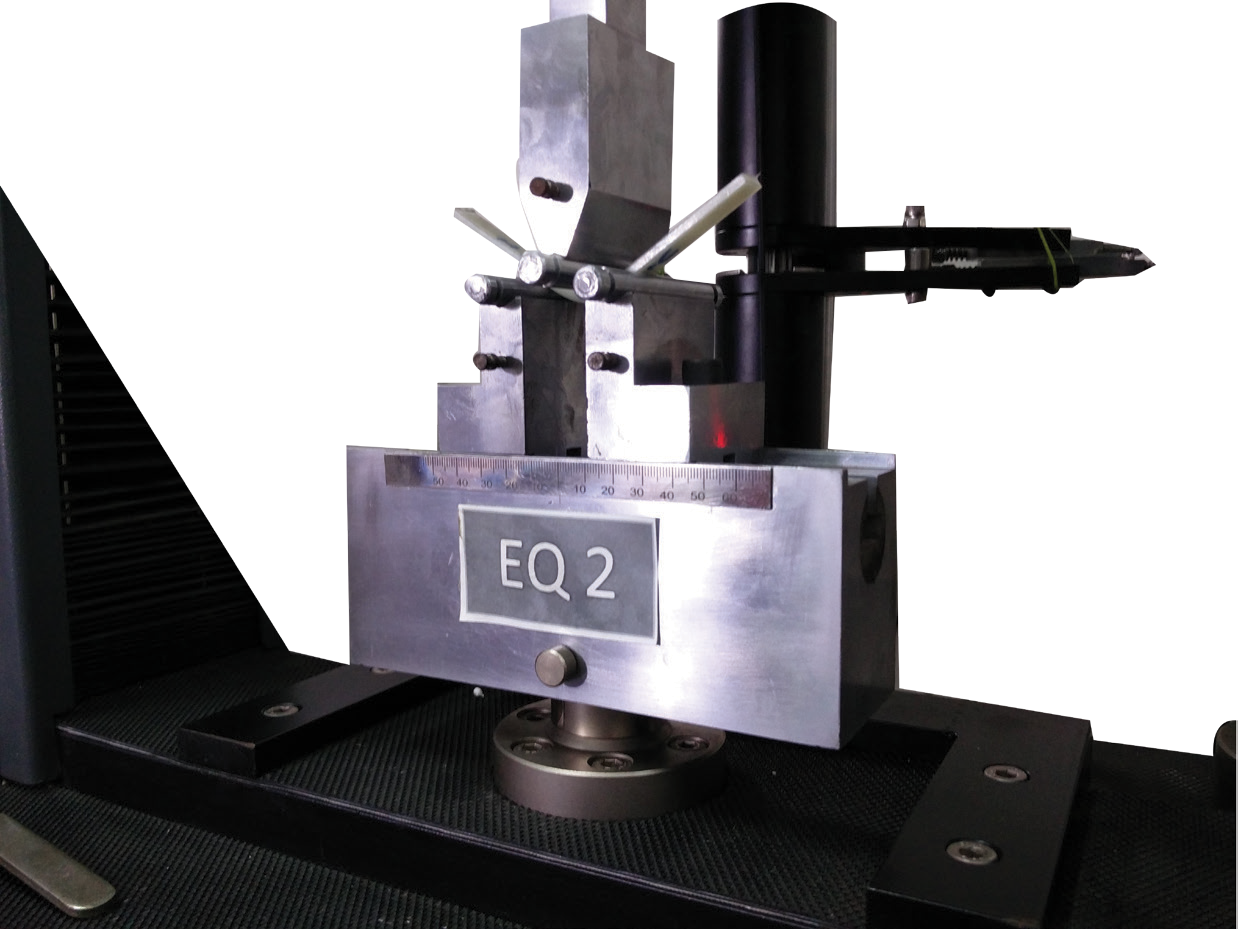

This test measures the abrasion resistance of rubbers and thermoplastic elastomers during the performance under abrasive condition. The method involves moving a specimen across the surface of a rotating drum with an abrasive sheet.

ASTM.png)

The evaluation of crack growth of vulcanized rubber when exposed to repetitive flexing is done by this test. The deterioration on Dynamic Fatigue can also be performed. These tests are performed either at room temperature and also at elevated temperatures

he property of Resilience of rubber is a function of its dynamic modulus and internal friction. The test can be performed to determine the impact resiliene of solid rubber by measurement of vertical rebound of a standard dropped mass.

Deterioration of rubber properties occur when exposed to Ozone atmosphere. The resistance of rubber to specific ozone concentration is determined under a specific tensile strain and temperature.

This test estimates the resistance of Rubber products to the effects of ozone cracking and outdoor weathering. The test can be performed moulded or extrude soft rubber materials and sponge rubber such as weatherstrips etc.

The determination of resistance to cracking of rubber products when exposed to ozone under dynamic strain condition is measured.

Polymeric materials get hard and brittle when subjected to low temperatures. Evaluations of characters on low temperatures are carried out at Maeon laboratories.

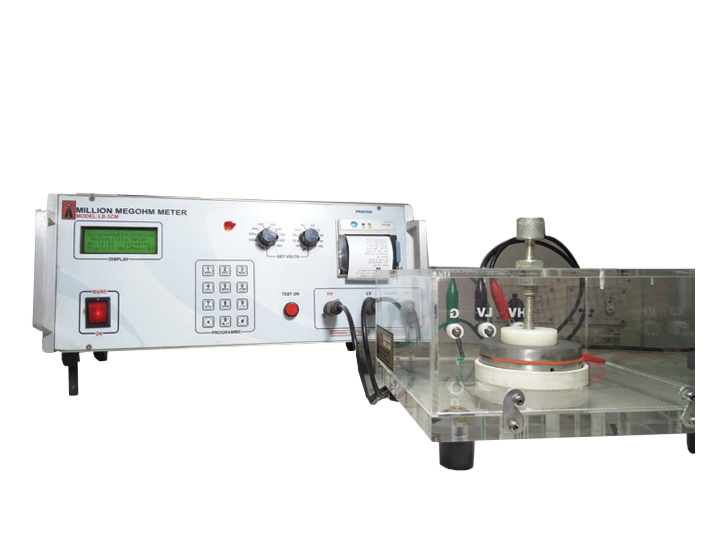

Surface resistivity is the resistance to leakage current along the surface of an insulating material. Volume resistivity is the resistance to lakage current through the body of an insulting material. Measurement of these resistance characters can be performed at MAEON laboratories.

This test metod utilizes the measurement of current flow through a material and the voltage drop across a section of the material to calculate the volume resistivity

The polymer contained in a cured and uncured compounds can be determined by Infrared spectrophotometry. Infrared Spectrum is also used for Chemicals to identify an unknown material within a group of Rubber/Plastic chemicals. The infrared spectrum of the test specimen is superimposed on a reference spectrum and compared if the two are identical or not.

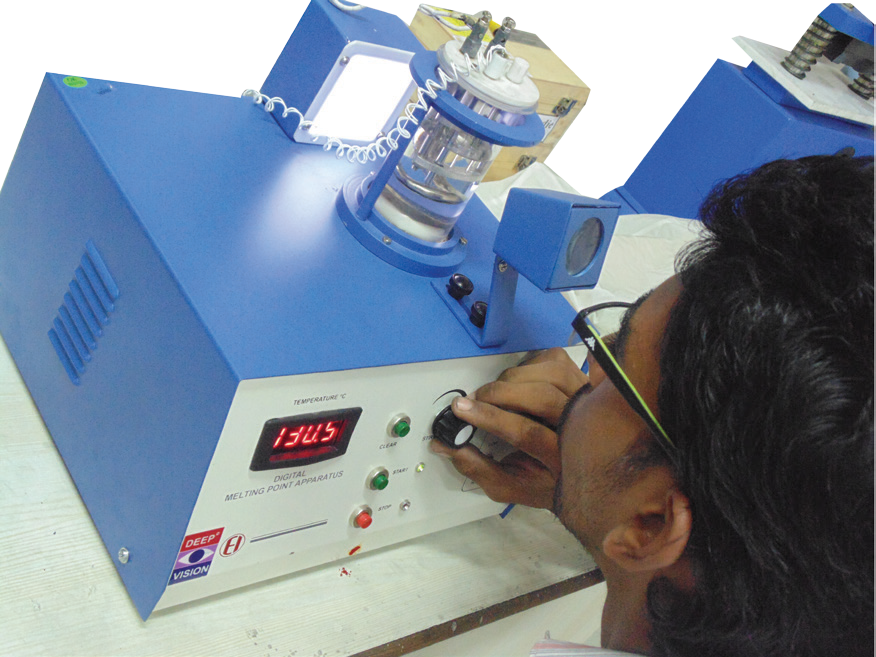

Melting point is determined for rubber processing chemicals for verifying quality of material. Melting point values which are deviating from known standard substance indicate poor quality.

Latex foam material / products can be evaluated for its properties on air ageing, compression deflection, load deflection, flexing, low temperature properties, static fatigue etc...

Sponge rubber and expanded rubber products can be evauated for its properties. Some of the properties tested are Compression deflection, heat resistance, fluid resistance, compression set, water absorption, ozone resistance etc.

Rubber products and compounds are analysed for type of polymer and quantity of polymer. dualitative and quantitative determination of nonrubber constituents are carried and some of the tests carried out are listed:

The composition of compound of rubber / plastics such s Low boiling fractions, polymer, carbon and fillers are quantitatively determined by TGA – Thermogravimetry. A small mass of test sample is subjected to controlled heating under specific environment and the mass loss over a temperature range is measured.

The Glass transition - temperature of materials is determined by DSC Procedure. The changes in the heat flow when samples is heated / cooled at controlled rate through the glass transition region is analzed to provide the Tg temperature. Other measurements from DSC include Specifc Heat, Crystallation temperature, Thermal stability, Decompostion temperature, Oxidative Induction Times etc…

IRHD International Rubber Hardness Degrees – Like Shore Scale - is a measure of Hardness of elastomeric materials. In this method, a spherical indentor, indents the sample under a minor and major load. The differential indentation depth is measured and reported directly in IRHD UNITS. IRHD-Micro is used for measuring specimens of lower thickness.

Maeon laboratories has facility for determining Dielectric properties of insulating materials plastic composites and elastomer compounds used commercially for insulation purposes. Sheets, extrusions, coatings, hoses and cellular materials can be tested for this parameter.

Rubber articles deteriorate on weathering, to accelerate the effects produced by light, heat and moisture in the natural environment, a UV source with heat and moisture weatherometer is used. After the specified period of exposure the rubber article is examined for property changes.

Rubber crystallises and stiffens at low temperature. The study of temperature of retraction of rubber gives an idea of performance characteristics at subzero temperatures.

The flammability properties of material when subjected to a small open flame is studied under different orientations, to evaluate its behaviour usage conditions.

Dielectric properties of polymeric materials used for Electric insulations are evaluated by this standards and test provides a value of voltage to breakdown / dielectric strength.

The insulation characteristics and capacitance with its ac loss characteristics are useful in evaluating rubber and plastics materials for its function. These parameters can be determined at MAEON laboratories.

Polymer materials deteriorate on exposure to light, moisture, heat etc… This test provides information on weathering characteristic when subjected UV light, water and heat on stipulated cycle and durations.

The composition of compound of rubber / plastics such s Low boiling fractions, polymer, carbon and fillers are quantitatively determined by TGA – Thermogravimetry. A small mass of test sample is subjected to controlled heating under specific environment and the mass loss over a temperature range is measured.

The Glass transition temperature of materials is determined by DSC Procedure. The changes in the heat flow when samples is heated / cooled at controlled rate through the glass transition region is analzed to provide the Tg temperature. Other measurements from DSC include Specifc Heat, Crystallation temperature, Thermal stability, Decomposition temperature, Oxidative Induction Times etc.,

The determination of the engineering characteristics and the physical properties of O Rings can be evaluated.