Tensile properties of Plastics provide very useful information for its engineering design purpose. Characteristics such as Tensile strength, Elongation, Elongation at Yield, Modulus of elasticity and other tensile properties can be determined.

The compression set taking place under constant stress / strain in media / air is evaluated. The test is intended to measure the ability of rubber to retain elastic properties after prolonged

Plastics show significantly different Absorption energy when subjected to an impact load. A measure of impact resistance of material is useful for Quality estimation purposes.

The Charpy Impact test indicates the energy of break standard test specimen under Standard conditions with notching.

This test is of prime importance for the Identification of material. It is also used to indicate us the physical changes if any, loss of plasticisers, absorption of solvent or because of any other cause.

MFI is largely influenced by the material’s physical properties, molecular structure and the rheological character. The test helps to determine the uniformity of the flow rate of polymer at a particular condition.

A measure of the Vicat softening temperature of plastics is useful for the characterization of plastics by its heat-softening qualities.

The test method covers a procedure to determine the temperature at which plastics deform when it is subjected high temperature and load.

Rate of burning of plastics, and also rate and extent of burning characterises are studied for understanding processing character and deterioration

Evaluation of Plastic products functioning under chemical contact for mechanical property changes is important for such products. Extend of deterioration in properties can be estimated after immersion in the specified chemicals.

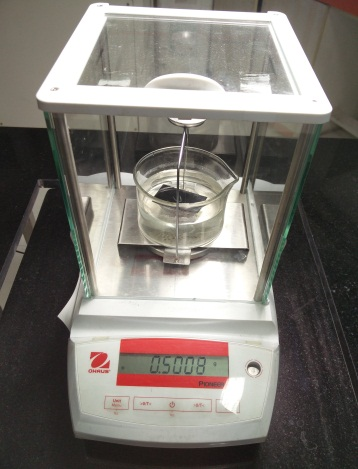

An estimation of water absorbed in Plastic material when immersed into it, can be evaluated at MAEONL.

Tear resistance which is the ultimate resistance to rupture is estimated. The force to initiate tear for flexible plastic films and sheetings is determined.

.png)

Quantification of carbon black contained in Olefinic plastics can be performed at MAEON laboratories. This test is useful for investigative, reconstructions and quality control purposes.

The polymers in a given material or product can be determined by Infrared spectrophotometry. The infrared spectrum of the test specimen is superimposed on a reference spectrum and compared for determination of polymer used.

The composition of compound of rubber / plastics such as Low boiling fractions, polymer, carbon and fillers are quantitatively determined by TGA – Thermogravimetry. A small mass of test sample is subjected to controlled heating under specific environment and the mass loss over a temperature range is measured.

Maeon laboratories offer testing of plastics for the determination of Transition temperatures, such as Entahalpies of Fusion and Crystallization of Polymers – including Tm, Tg, Tc. Other measurements from DSC include Specifc Heat, Thermal stability, Decomposition temperature, Oxidative Induction Times etc.,

Maeon laboratories has facility for determining Dielectric properties of insulating materials plastic composites and elastomer compounds used commercially for insulation purposes. Sheets, extrusions, coatings, hoses and cellular materials can be tested for this parameter.

Maeon laboratories has test facilities to induce property changes in polymeric materials, which are associated with end-use conditions, such as sunlight, moisture and heat. The deterioration caused is evaluated for its end use.

Thin sheetings / films of polymers can be tested for its tensile properties using this method. Films of any thickness below 1.00 mm can be taken up for evaluation.

Determination of Flexural properties are important for specifying grades and the control of quality. Flexural Strength, Modulus, Flexural strain. A rectangular test specimen is placed on 2 supports and loaded at the centre of supports.

Maeon laboratories has facility for evaluating plastics for its behaviour at low temperature. A test device determines the brittleness point of plastics r under impact at low temperature.

Maeon laboratories has facility for determining Dielectric properties of insulating materials plastic composites and elastomer compounds used commercially for insulation purposes. Sheets, extrusions, coatings, hoses and cellular materials can be tested for this parameter.

Maeon laboratories has test facilities to induce property changes in polymeric materials, which are associated with end-use conditions, such as sunlight, moisture and heat. The deterioration caused is evaluated for its end use.

The composition of compound of rubber / plastics such s Low boiling fractions, polymer, carbon and fillers are quantitatively determined by TGA – Thermogravimetry. A small mass of test sample is subjected to controlled heating under specific environment and the mass loss over a temperature range is measured.

Maeon laboratories offer testing of plastics for the determination of Transition temperatures, such as Entahalpies of Fusion and Crystallization of Polymers – including Tm, Tg, Tc. Other measurements from DSC include Specifc Heat, Thermal stability, Decompostion temperature, Oxidative Induction Times etc.,